Supporting Product, Manufacturing, and Process Engineering

Design, validation, manufacturing engineering, and industrial consultancy services – helping OEMs and Tier-1s develop, test, and industrialize vehicle systems with speed and precision across passenger cars, commercial vehicles, off-highway equipment, and two/three wheelers.

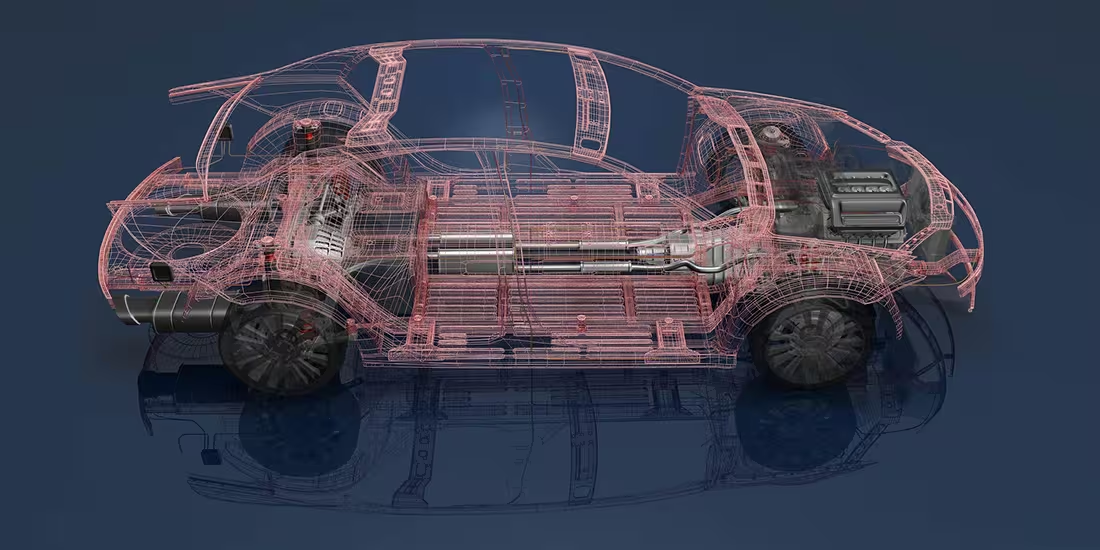

Product Engineering

We provide product engineering solutions that boost efficiency and innovation. From concept to execution, we deliver scalable, high-performance solutions using the right technologies to support future-ready business growth.

Styling

We interpret design functionality, creating forms and volumes that meet production needs. We support you from concept to product design and perfect Class A surfaces.

Benchmarking

Identify trends and best practices for unique design inspiration.

Style Definitions

Create vehicle look and feel through sketches, renderings, and 3D models.

Sketching

Explore design options quickly before detailed stages.

Rendering

Visualize designs with realistic lighting and materials.

Regulatory Compliance

Implement modern tools to meet safety standards.

Concept Development

Concept development drives product creation. We lead the convergence between customer needs and ideal technical solutions for performance, ergonomics, safety, and user experience.

Concept Definitions

Align appearance, functionality, and technology to communicate product vision.

Engineering Feasibility

Evaluate and refine technical aspects for production viability.

Surface Development

Create cohesive, appealing design proposals and prototypes.

Ergonomic Checks

Ensure comfortable user experience through optimized component placement.

Fixing Strategy

Develop feasible, scalable production plans.

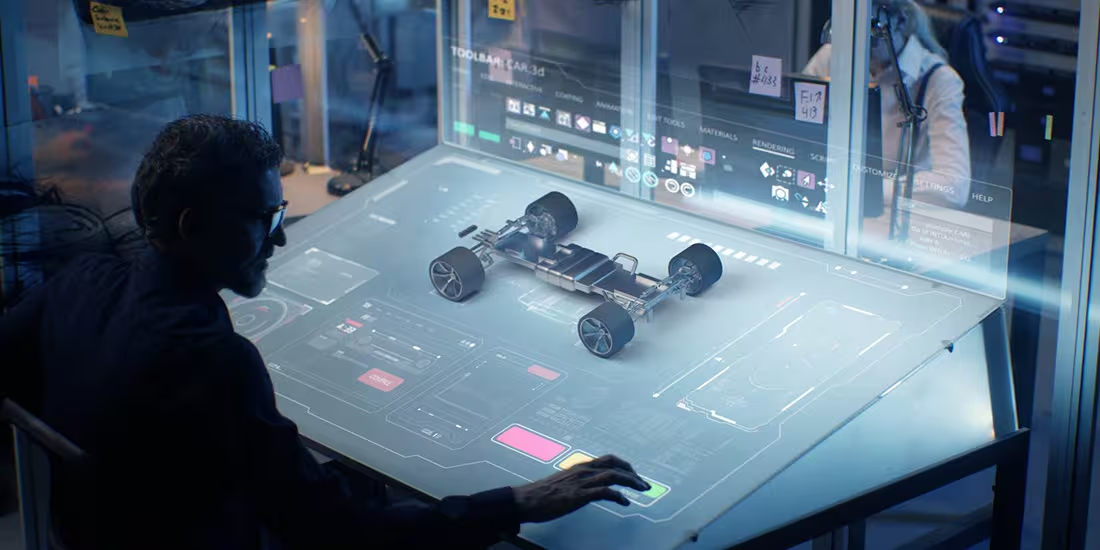

Feasibility

Our feasibility analysis coordinates innovative designs with vehicle-specific characteristics, enabling better part design, increased quality, and reliable long-term performance while reducing costs and time to market.

A Surface Check

Verify exterior body surfaces meet aesthetic and functional requirements.

Packaging Studies

Optimize component layout to meet performance and safety requirements.

Digital Mock-Up (DMU)

Create 3D models to simulate design, manufacturing, and assembly.

Master Section Creation

Establish design direction and target specifications.

Regulatory, Performance, Safety Checks

Evaluate designs against standards.

Fit Function Requirement Check

Evaluate vehicle design for regulatory, standards & performance requirements set by the OEM.

Design & Validation

We optimize development periods and reduce costs by validating products early. Our experts take responsibility for functional design of components, systems, and complete vehicles.

Engineering Design

Ensure cost-effective and practical manufacturing.

GD&T Plan

Ensure design accuracy, reduce variability, improve product quality.

Virtual Validation

Identify risks and make informed development decisions.

Engineering Proto Release

Prepare prototypes for testing and validation before production.

PLM

We deliver end-to-end PLM services – strategy, implementation, integration, and migration – helping automotive clients accelerate innovation, streamline product data management, and connect CAD, ERP, and MES systems for enterprise – wide collaboration.

Manufacturing Engineering

We optimize manufacturing processes with advanced engineering solutions, enhancing efficiency, precision, and scalability for industrial success. By integrating innovation and technology, we streamline production and drive excellence.

Pre-Series Development

We minimize production issues and ensure smooth mass production start through comprehensive testing and validation, supporting all necessary development steps even at early stages.

Tolerance Analysis

Ensure parts meet specifications before production.

Pre-Series Manufacturing

Testing and validation of manufacturing processes before starting full-scale production.

Pre-Production Support

Prepare for mass production through tooling release and process optimization.

Plant Engineering

We help automotive brands balance quality, cost, and innovation by integrating people, processes, and technology for better efficiency, safety, and performance.

Plant Layout

Optimize space use and improve efficiency.

Processing Studies

Optimize manufacturing processes through systematic time analysis.

Process Validation

Evaluate equipment and procedures to ensure product quality.

Industrial Automation

We offer extensive experience in assembly solutions, from operator-assisted stations to fully automated robotic lines.

Assembly Line Design

Optimize assembly processes for efficiency and resource utilization.

Detailing

Create technical drawings, specifications, and manufacturing process plans.

BOM

Provide guides for procurement, production, and quality control.

Build Support

Validate manufacturing processes for quality, cost, and delivery.

Industrial Consultancy

We provide expert industrial consultation to optimize operations, enhance efficiency, and drive business growth. Our strategic insights and innovative solutions help industries overcome challenges, streamline processes, and achieve sustainable success.

Pre-Series Development

Driving manufacturing excellence through a structured approach: we engage stakeholders early, diagnose process gaps, propose targeted improvement solutions, facilitate implementation on ground, and institutionalize best practices. Empowering sustainable growth with Industry 4.0-ready strategies.

Case Studies

Explore in-depth success stories, strategic solutions, and real-world impact through our featured projects.